More info

Over 3 billion T-Shirts are sold each year, of which, a majority are printed. T-Shirt printing started in the 1950's in Miami, Florida, when companies started decorating their T-Shirt to promote their business. Cut to today, adding your logo or design goes a long way in making that plain T-Shirt unique. Before you create that Custom T-Shirt, you may want to know which printing method to use. Below you'll discover the various methods of T-Shirt printing available which you can use. For all these methods we shall tell you their respective advantages and drawbacks. After reading this post, you will have a fair idea of which method of t-shirt printing to use.

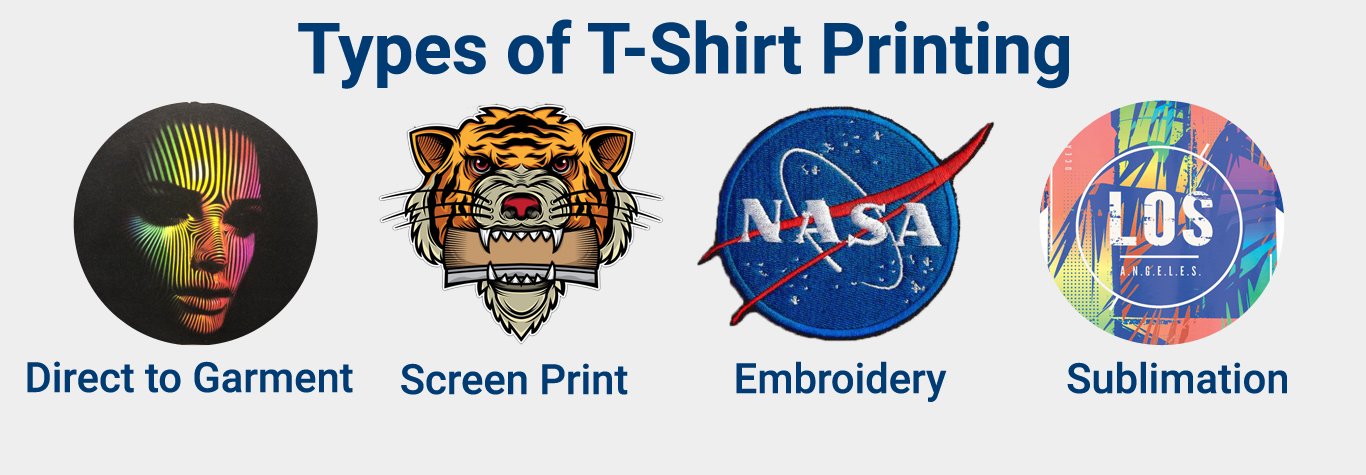

6 Techniques of T-Shirt Printing:

Screen Printing

Screen printing is still the most proffessional way of printing on t-shirts. Another name for this technique is silk screen printing. If you have a t-shirt or polo shirt with a soft print with consistent colours, this is most probably the type of printing. These prints remain vibrant, bright and last for long. You can count on screen print for most of your t-shirt printing needs including polo shirts, hoodies and other apparel. However, it may not be the best option for all occasions.

Screen printing requires you to create a stencil or template of the design. This is held in place with the help of a screen which is, usually, made of nylon mesh. The screen is the placed in position on top of the t-shirt to be printed. Ink is then flooded onto the screen and spread to ensure it fully spread on the screen. The ink passes through the wire mesh and the stencil of the design to print onto the t-shirt. Excess ink on the screen is wiped away. The screen is then removed and the t-shirt cured, cured and ready!

Screen Printing has the following advantages:

- Screen printing method is ideal for high quality printing of t-shirt designs, because it guarantees the exact replication, consistent quality and durability

- It is cost effective in volume.

- It is also scalable as the mesh screen and templates can be reused several time.

Screen Printing however has it's disadvantages:

- Screen printing is not feasible for single t-shirt orders. iLogo has a minimum requirement of 6 t-shirts for screen printing.

- Screen printing is also not suitable for complex designs with multi-colours and gradients.

- Screen printing takes longer for set up as screens and stencils need to be made.

- As each colour needs to be seperated as unique to be used through stencil, colour accuracy might become an issue

Direct to Garment(DTG) Printing

Next on the line is the Direct to Garment(DTG) method. This is a relatively new method of t-shirt printing and was introduced only in 2005. It involves printing directly on the t-shirt. It is printed using a DTG Printer. This works exactly the same way printing is done by an inkjet printer on paper.

Being able to print directly on the t-shirt with a machine has the following advantages:

- Detailed Printing - As this prints directly on the t-shirt, complex designs and colours can be printed.

- One offs - As there is no set up required, it is ideally suitable for one off prints.

- Quick delivery - As it can be printed directly on the t-shirt, this can be printed at short notice.

Considering DTG printing is an emerging technology, it has some inherent disadvantages:

- Price - The DTG printer and the ink used is relatively expensive. And as the cost increases linearly with volume, it is not cost effective for larger runs.

- Consistency - The prints are not consistent and depends a lot on variables like temperature, material of the t-shirt and pretreatment liquid.

- Placement - As the print is done with machine on a flat bed, the print cannot be done at unconventional design positions

- Colour - Colour matching of the print cannot be done, as the software and machine interprets the colours by converting RGB to CMYK.

- Quality - The print quality is not as good as Screen Prints. The print may fade after a few washes

Vinyl Cut Printing

Vinyl cut printing is the technique where vinyl sheets are cut as per the design using a CAD plotter and cutter. This cut design is then printed onto the t-shirt using a heat press machine. It is widely used add names and numbers onto sports t-shirts. It can be done on both dry-fit sports jerseys and cotton t-shirts. Vinyl cut Printing allows for different types of prints like reflective prints, neon prints, glitter prints, metallic foil prints as well as prints in an colour. Vinyl cut print works well for slogans, small graphics and words.

The advantages of Vinyl Cut Printing are:

- Durability - No fading cracking of print

- Quick Turnaround - As there is no set up involved, they can pretty quickly.

- Ideal for low quantities - As there is no set up cost, they are suitable for one-off prints.

- Print colour and material options - As the types and colours of vinyl(colours, giltter, metallic foil,reflective) are innumerable.

There are a few disadvantages of CAD Vinyl Cut Printing:

- Print Size - The bigger the print, the heavier the garment gets.

- Print Quality - Print is not as soft as screen prints.

- Not Cost Effective for Large orders - It is not cost effective for large order as the cost increase linearly with quantity unlike Screen printing.

Sublimation Printing

Sublimation printing is what is used to get an all over print on a t-shirt. However, this can only be done on polyester t-shirts. It is capable of transforming the whole t-shirt into a piece of art. Sublimation print can only be done on lighter colours. In sublimation printing, the design is first printed onto a heat transfer paper. This paper is then placed on the t-shirt to be printed and high temperature and pressure through a fusing machine then applied. With the application of heat, the t-shirt pores expand and the sublimation dye on the paper turns into liquid and gas and passes onto the pores of the t-shirt fabric. On cooling, the pores again contract and the t-shirt is now printed with the design.

The advantages of Sublimation Printing are:

- Print size - Can do all over prints.

- Design range - can print any design, colour and range of colours.

- Durable - Prints are extremely long lasting.

- Great Print quality - The print is within the fabric itself and cannot be felt

The disadvantages of Sublimation Printing are:

- Fabric - Sublimation printing can only be done on polyester fabric.

- T-Shirt Colour - Sublimation printing can only be done white and light colours.

Heat Press Printing

Heat Press Transfer Printing is basically transferring the design from one surface to the other using heat and pressure. In this case, you transfer the design from a heat press paper onto the T-Shirt using a heat press fusing machine. It is also used for several other products like mugs, ceramics, stickers etc.

The advantages of Heat Press Printing are:

- Straightforward to do - printing a paper and transferring it onto a t-shirt with a heat press machine does not require much skill.

- Complex Designs - Complex designs can be printed on paper easily and then transferred to the t-shirt.

- Full colour Printing - As you print on paper first, we can print multiple colours with gradients

The disadvantages of Heat Press Printing are:

- Print Quality - The print quality is inferior to other forms of printing.

- Slower Process - As each paper needs to be printed and the design transferred individually, it is not suitable for large orders.

Embroidery

This is not printing in the conventional sense but a standard way of decorating a T-Shirt. This is the ideal and most widely used technique for corporate t-shirts and corporate shirts. Embroidery is the oldest form of t-shirt printing who's history can be traced back to 30,000 BC. In embroidery, the design is directly sown onto the t-shirt with a sewing machine.

The advantages of Embroidery on T-Shirts:

- Appearance - Embroidery looks classy and elegant.

- Durability - Embroidery is extremely durable and long lasting

The disadvantages of Embroidery are:

- Design limitations - very fine designs with multiple colours is not possible.

- Colour limitaions - designs with gradients cannot be embroidered. Also, there is a limitation in the number of colours in the design to 8

Conclusion

There are many methods to print on T-Shirts. Each method has it's unique advantages and disadvantages. Each method is best suitable for their own different occasion. At iLogo we provide T-Shirt Printing Services right at your doorstep at all locations across the world.